At PSB GmbH, we understand that industrial automation demands PC solutions that deliver unwavering performance under challenging conditions. Our Industrie Touch PCs—robust panel computers designed for automation—merge decades of engineering know-how with forward-thinking innovation. Engineered for durability, these systems withstand harsh environments, thanks to features like IP65-rated enclosures, advanced filtering, and support for extended temperature ranges. Every panel PC we develop is tailored to the unique technical and operational needs of each client, reflecting our commitment to custom, project-specific solutions. Working independently from any single manufacturer enables us to select and integrate the best technologies available, ensuring optimal reliability and longevity. Through a deeply collaborative approach, our team ensures that every system enhances process efficiency and operational safety.

What is an Industrial Touch PC? Definition, Advantages, and Application Areas

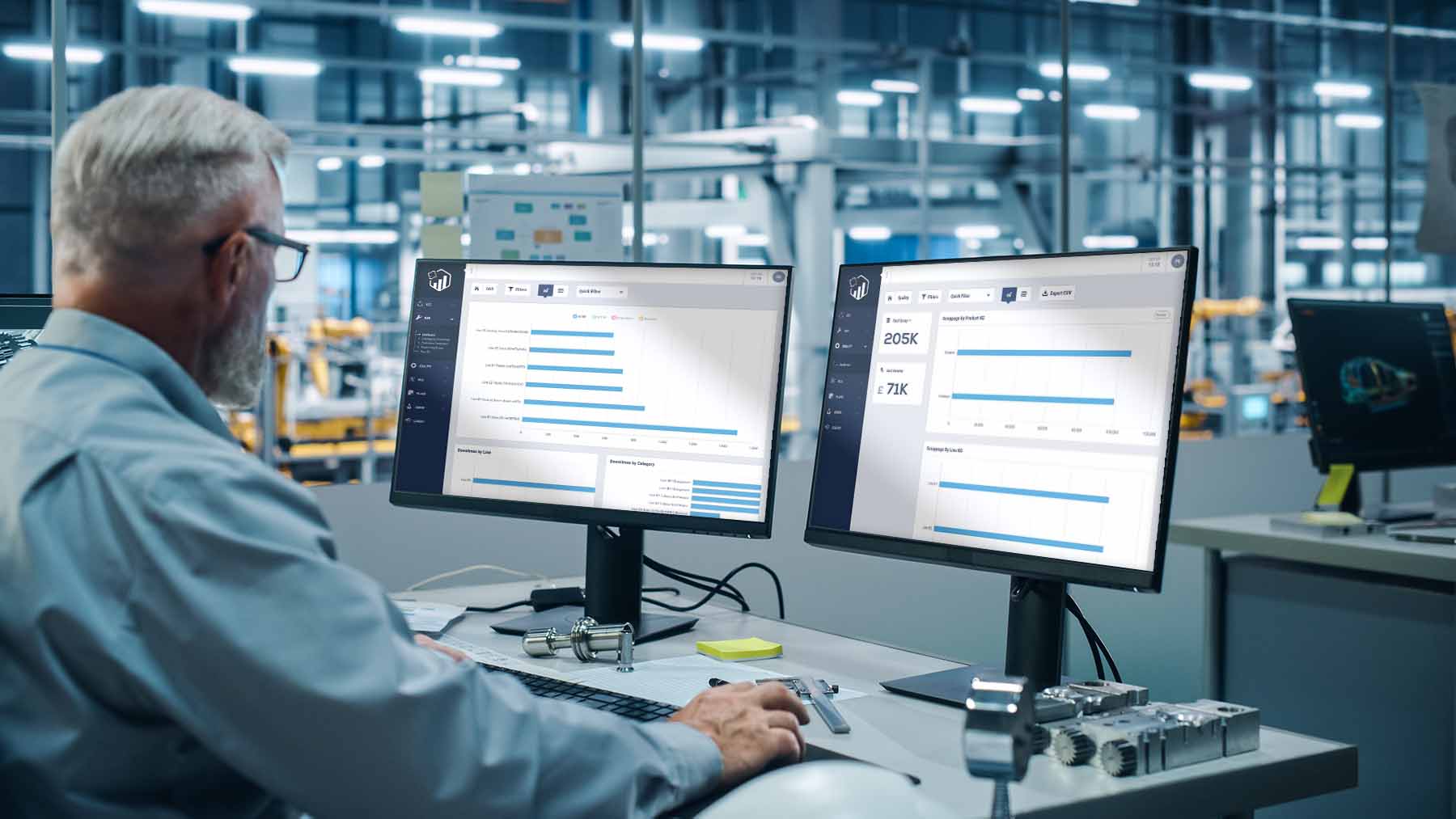

An Industrie Touch PC (Industrial Touch PC) is a robust and specially engineered computer designed for deployment in harsh industrial environments. Unlike consumer-grade PCs, these devices are built to withstand dust, humidity, extreme temperatures, and mechanical impacts, making them essential for process automation, HMI (Human Machine Interface), and real-time control of machinery. The integration of a projective-capacitive (PCAP) multi-touch display enables operators to interact efficiently, even with gloves or in wet conditions.

The benefits of an Industrie Panel PC include high reliability, 24/7 operation, minimal downtime, and tailored protection classes such as IP65, IP66, or IP69k. These PCs ensure stable performance under vibrations, electrical noise, and exposure to cleaning agents, making them ideal for food processing, automotive manufacturing, and pharmaceuticals. For more on protection levels, see this detailed comparison: Rugged PC IP65/IP67: Comparing Protection Levels.

- Robustness: Resistant to dust, water jets, and shocks

- Fanless Design: Reduces wear and operation noise

- Versatility: Suitable for SCADA/MES integration, machine control, and BDE terminals

- Hygiene: Stainless steel variants and flat surfaces for easy cleaning

Key Application Areas

- Automated production lines (machine control, HMI)

- Food & beverage industry (hygienic Edelstahl Panel PC IP69k versions)

- Logistics and warehousing

- Pharmaceutical and chemical processing (requirements for IP protection, cleaning resistance)

- Energy & utilities (rugged Fanless Panel PC for outdoor substations)

Technical Specifications and Performance Classes

Modern Touch Panel PCs are defined by their technical features, which determine suitability for various industrial requirements. Understanding these specs helps in choosing the best system for a specific environment.

- Display Sizes: Common options include 15 Zoll Industrie Touch PC, with variations from 7” to 24”.

- Touch Technology: Projective-capacitive (PCAP) or resistive touch, both supporting single and multi-touch operations. Multi-touch enhances usability in complex control applications.

- Processor: Choices range from efficient Atom processors to powerful Intel Core Panel PC variants for demanding real-time tasks.

- Protection Classes: IP65 Touchscreen for water-jet resistance, up to IP69k for high-pressure steam cleaning, critical in food processing (Industrie Touch PC mit IP65).

- Fanless-Design: Lüfterloser Industrie-PC (fanless panel pc) supports dust-free, low-maintenance long-term operation.

- I/O Interfaces: Rich connectivity including USB, Ethernet, serial ports, optional RFID and NFC.

- Mounting: VESA, panel, or wall mounting for flexible integration.

- Operating Systems: Commonly Windows Industrie Panel PC and Linux-based systems.

- Special Technologies: Optical Bonding for superior screen readability in bright and humid environments.

| Model | Display Size | CPU | Protection Class | Touch Tech | Mounting |

|---|---|---|---|---|---|

| HMI Panel PC Classic | 15” | Intel Core i5 | IP65 (front) | PCAP Multi-Touch | Panel, VESA |

| Stainless Steel Panel PC | 19” | Intel Atom | IP69k | Resistive | VESA |

| Fanless Industrial PC | 17” | Intel Core i3 | IP66 | PCAP | Panel |

| Advanced Touch Panel | 21.5” | Intel Core i7 | IP65 (all sides) | PCAP Multi-Touch | Wall, VESA |

Typical Performance Classes

- Entry Level: Atom-based systems – energy efficient, ideal for simple data capture or BDE terminals.

- Standard: Core i3/i5 CPUs – balanced for HMI applications and machine visualization.

- High-Performance: Core i7/Xeon processors – for SCADA/MES, real-time visualization, and AI-driven applications.

Real-world suitability also depends on EMC standards. For details about the safety and legal considerations, consult EMC Protected Computers: Safety & Legal Requirements.

Popular Models and Manufacturer Overview

The market for Industrie Panel PCs includes many established manufacturers, offering specialized devices for diverse requirements. Key players provide ranges from compact, fanless operator stations to fully hygienic and high-performance HMI systems. Typically, manufacturers focus on longevity, extended product life cycles, and compatibility with industrial software environments.

- Hygienic Stainless Steel Panel PCs: Especially in pharmaceuticals and food industry, Edelstahl Panel PC IP69k models meet the most stringent hygiene and washdown requirements.

- Compact Fanless Panel PC: Designed for tight spaces or noise-sensitive areas – a great match for automation cabinets and SCADA installations. Learn about the importance of quiet operation in industrial racks at Low-Noise Rack PC: Quiet Solutions for Your IT Rack.

- High-Performance Windows Industrie Panel PC: Used for advanced machine control, MES/SCADA integration, and visualization dashboards.

- Customizable Panel PC for Machine Control: Modular devices supporting special I/O, RFID, and multi-OS environments, tailored to production needs.

Most leading vendors offer long-term availability and robust support. Read more about ensuring system reliability in industrial projects in the article Embedded PC Long-Term Availability: Secure Your Projects.

Selection Criteria for Your Industrial Touch PC

Choosing the right Touch Panel PC means balancing performance, hygiene requirements, budget, and installation needs. Here are practical selection guidelines industry professionals should consider:

- Protection Class: Determine required IP rating (e.g., IP65 for indoor dust/water resistance or IP69k for hygienic washdown zones).

- Performance: Match processor and memory to application requirements – use Intel Core Panel PC for real-time visualization, Atom for simple data logging.

- Mounting & Integration: Ensure compatibility with panel cutouts, VESA arms, or enclosure conditions to optimize workspace.

- Touch Technology: Opt for multi-touch (PCAP) for intuitive operation, resistive if gloves or special work conditions apply.

- Connectivity: Review number and type of I/O interfaces needed, including industrial fieldbus, USB, and RFID.

- Hygiene: Stainless steel housing and seamless front for food/pharma environments.

- Software Compatibility: Confirm OS support and SCADA/MES integration.

Industrial Panel PC Purchase Checklist

- Required protection class? (e.g., IP65, IP69k)

- Fanless and maintenance-friendly design desired?

- Operating environment: Hygiene, vibration, temperature?

- Display size and type: 15 Zoll, multi-touch needed?

- Do you need RFID/scanner integration?

- Long-term availability for project stability?

For a deeper dive into performance and certification, especially for electromagnetic compatibility, find insights in EMC Tested Industrial PC: Importance & Benefits.

Tips for Integration and Maintenance

Proper integration of an Industrie Touch PC ensures long-term stability, user-friendly operation, and efficient maintenance. Here are expert recommendations for setting up and servicing your system:

- Mounting: Use VESA or panel mount for easy access and maintenance. Prioritize vibration-damped assemblies for heavy machinery.

- Sealed Cable Management: Ensure all cable entries maintain required IP protection level.

- Regular Cleaning: For hygienic models (Edelstahl Panel PC IP69k), use appropriate cleaning agents, and avoid abrasive tools.

- Firmware and Software Updates: Plan routine updates to minimize downtime and maintain security.

- Component Replacement: Select systems designed for tool-less maintenance (SSD, RAM, etc.).

- Documentation: Maintain up-to-date diagrams, parts lists, and configuration files for all HMIs.

For further information on reducing noise and optimizing installation in control cabinets, please review Low-Noise Rack PC: Quiet Solutions for Your IT Rack.

Pay special attention to electromagnetic compatibility and legal compliance with every installation, as described in EMC Protected Computers: Safety & Legal Requirements.

The role of robust panel PCs in automation extends far beyond basic computing—they serve as the pivotal interfaces between operators and complex machinery, often in mission-critical scenarios. At PSB GmbH, our extensive history in industrial IT solutions is built on a foundation of reliability, precision, and transparent communication with our customers. Through in-house development, rigorous burn-in testing, and scalable production, we guarantee consistent performance and long-term serviceability. Clients can trust in our ability to deliver not only technically advanced systems, but also dependable support throughout each phase of the project lifecycle. As automation requirements evolve, PSB GmbH remains committed to delivering robust, customized panel PCs that anticipate future demands and uphold the highest standards of industrial engineering.